-

- Accueil

- New machines

- Used machines

- Rectifieuses

- MILLING

- MILLING MACHINE

- VERTICAL MILLING CENTER 3 AXIS < 1000 mm

- VERTICAL MILLING CENTER 3 AXIS 1000 to 2000 mm

- VERTICAL MILLING CENTER 3 AXIS > 1000 mm

- CENTRE D’USINAGE VERTICAL PALLETISE

- CENTRE USINAGE VERTICAL 4 AXES @en

- CENTRE USINAGE VERTICAL 5 AXES @en

- HORIZONTAL MACHINING CENTER

- PORTAL MILLING MACHINE

- PETITES FRAISEUSES CNC @en

- BED TYPE MILLING MACHINE

- HORIZONTAL BORER

- FOREUSE @en

- LATHE

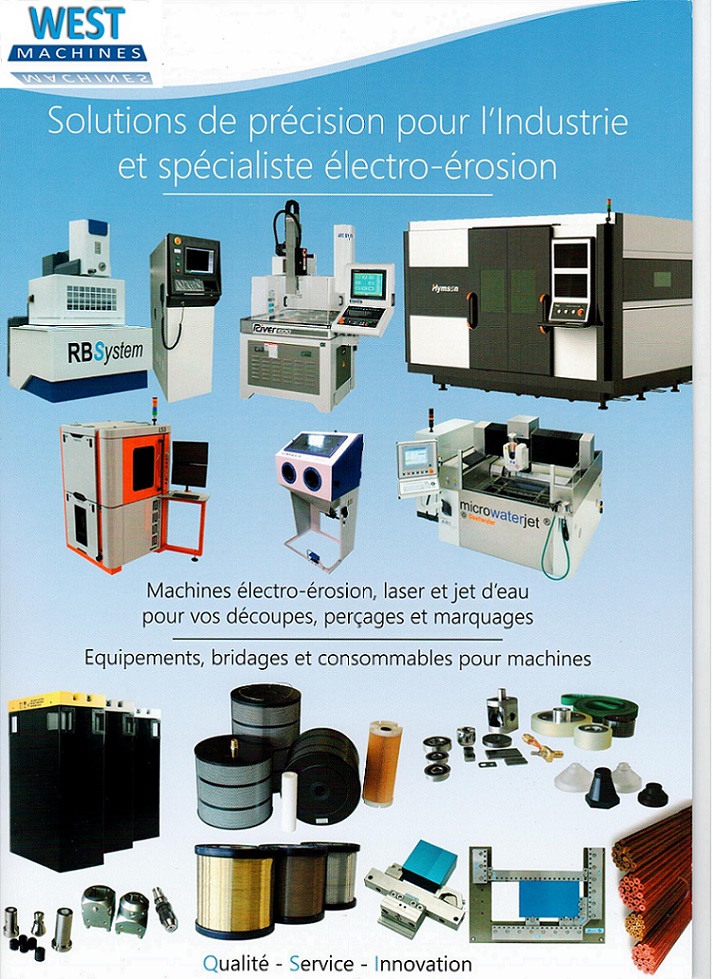

- ERODING MACHINE

- CONTROLE

- TOLERIE @en

- TAILLEUSES DE DENTURES

- MATERIEL DE MANUTENTION

- EQUIPEMENTS BRIDAGES

- Contact

- AFTER – SALES

- FUNDING

- ISO 9001 / 14001

- CAD – CAM

- LOGISTICS

- TRAINING

-

- Ma sélection (0)

-

Tel : +33 (0) 9 65 34 64 11

Fax : +33 (0) 2 40 71 82 43

Port : +33 (0) 6 09 70 57 59

Fax : +33 (0) 2 40 71 82 43

Port : +33 (0) 6 09 70 57 59

FOREUSE DEGEN UTB 1000 H/CNC – 2010/2020 – 1300 X 600 (HAUTEUR) X 1000 (PROFONDEUR DE PERCAGE) MM

- GENRE : FOREUSE CNC

- MARQUE : DEGEN

- TYPE : UTB 1000 H/CNC

1 Pc. CNC universal high pressure deep hole drilling machine

Fabrik : DEGEN

Type : UTB 1000 H/CNC

Year of built : 2010

technical overhaul : 2020

Comment / General : The machine is in a very good technical and optical condition.

The facility was technically overhauled in 2020.

No maintenance backlog!

Basic machine : 3 CNC axes (X, Y, Z-)

CNC control Heidenhain TNC 426 AC drives

Internal coolant supply Drilling arm with linear guide for direct drilling and milling

Rotary table manually

High pressure coolant system

Chip conveyor

2-way steady rests

Fully enclosed including sliding doors

Work performance :

– Drill diameter with gundrill 5 – 25 mm

– Milling 100 cm³ / min

– Thread M20 thread cutting

Travels :

– X axis (table across) 1300 mm

– Y axis (vertical drilling unit) 600 mm

– Z axis (quill) 1000 mm = drilling depth

– W axis (table lengthwise) 500 mm

– B – axis (NC rotary table) 0-360 ° manually swiveling

Drilling unit:

– Main spindle HSK 60 spindle

– spindle speed 100-4000 rpm

– Drive power at 60% ED 10 kW

Workpiece table (B axis) :

– table surface 1400 x 800 mm

– Rotatable 0-360 ° rotary axis manually

– Max. Table load 5.000 kg – 1 degree index – Hydraulic lifting and lifting

High pressure coolant system:

– Container size approx. 800 l

– Coolant pressure max. 90 bar

– flow rate max. 68l / min

– Paper band filter 50 μ

CNC Control: – Heidenhain TNC 426

– Tool wear and pressure monitoring

– Deep drilling technology programs

General data :

– Operating voltage 380 V / 50 Hz

– Control voltage 220/24 V DC

– Total connection approx. 20 kW

– Machine weight approx. 8,000 kg

– Space requirements according to the floor plan

Availability :

*- Immediately, subject to prior sale

Price : On Request*

Services at extra cost:

– Transport service including insurance policy

– Setup, installation, commissioning at the customer site on request

– 2 days employee training basic function machine + CNC on request

PRIX : Contactez-nous

|

|