-

- Accueil

- New machines

- Used machines

- Rectifieuses

- MILLING

- MILLING MACHINE

- VERTICAL MILLING CENTER 3 AXIS < 1000 mm

- VERTICAL MILLING CENTER 3 AXIS 1000 to 2000 mm

- VERTICAL MILLING CENTER 3 AXIS > 1000 mm

- CENTRE D’USINAGE VERTICAL PALLETISE

- CENTRE USINAGE VERTICAL 4 AXES @en

- CENTRE USINAGE VERTICAL 5 AXES @en

- HORIZONTAL MACHINING CENTER

- PORTAL MILLING MACHINE

- PETITES FRAISEUSES CNC @en

- BED TYPE MILLING MACHINE

- HORIZONTAL BORER

- FOREUSE @en

- LATHE

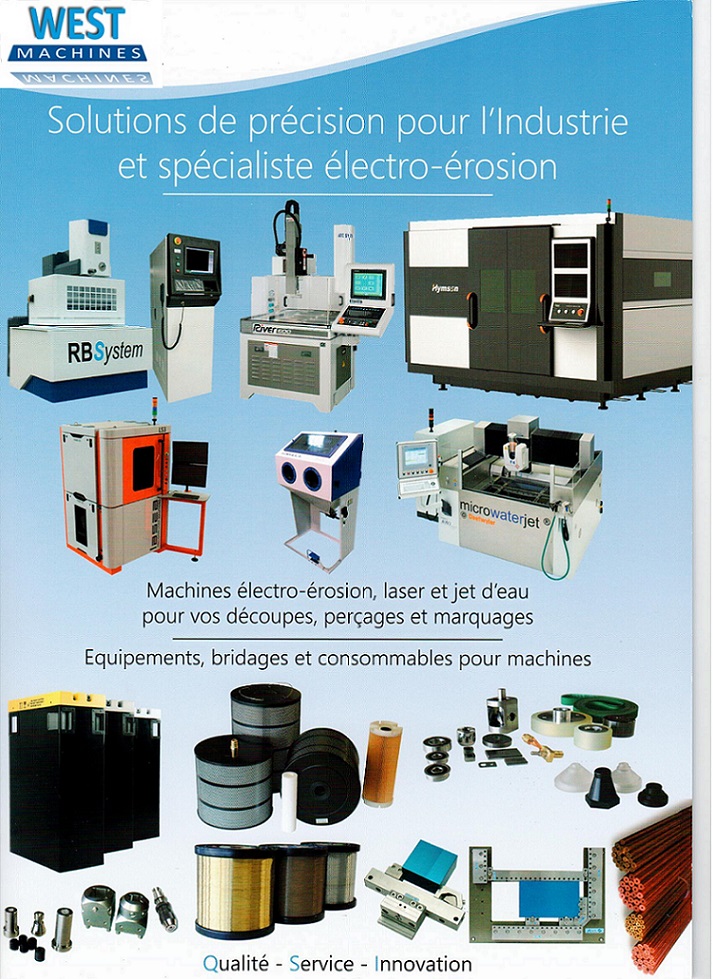

- ERODING MACHINE

- CONTROLE

- TOLERIE @en

- TAILLEUSES DE DENTURES

- MATERIEL DE MANUTENTION

- EQUIPEMENTS BRIDAGES

- Contact

- AFTER – SALES

- FUNDING

- ISO 9001 / 14001

- CAD – CAM

- LOGISTICS

- TRAINING

-

- Ma sélection (0)

-

Tel : +33 (0) 9 65 34 64 11

Fax : +33 (0) 2 40 71 82 43

Port : +33 (0) 6 09 70 57 59

Fax : +33 (0) 2 40 71 82 43

Port : +33 (0) 6 09 70 57 59

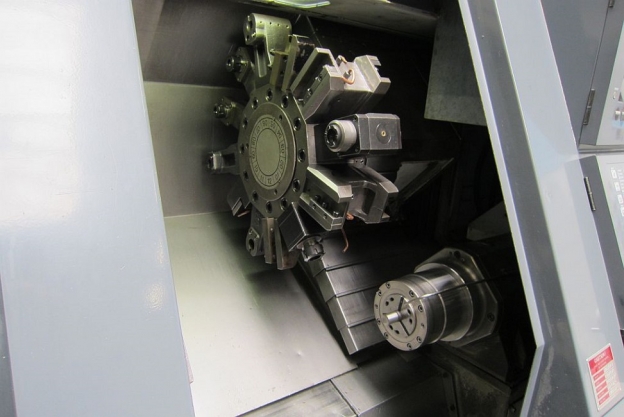

TOUR CNC BI-BROCHE AXE C MAZAK SQT 250MS – 1998 – BARRE DIAM 64MM

- GENRE : TOUR CNC BI BROCHE MONO TOURELLE AXE C

- MARQUE : MAZAK

- TYPE : SQT 250MS

| Manufacturer: | MAZAK |

| Modell: | Super Quick Turn 250 MS |

| Serial Number: | |

| New: | 1998 |

| CNC Control: | Mazatrol T-Plus |

| Maximum Swing | 525 | mm | ||||

| Maximum Swing over saddle | 350 | mm | ||||

| Maximum Turning Diameter | 300 | mm | ||||

| Maximum spindle bore for bar work | 64 | mm | ||||

| Min/Max.distance between chuck of both spindles | 534 | mm | ||||

| Workpiece transfer between 2 spindles | 8 | sec. | ||||

| Spindle speed | Main Spindle | 35-4000 | Rpm | |||

| Spilnose taper | Main Spindle | A2-6 | ||||

| Spindle motor | Main Spindle 30 min/continue | 18,5/15 | Kw | |||

| Maximum torque on spindle | Main Spindle | 333 | Nm | |||

| Spindle speed | Sub Spindle | 35-4000 | Rpm | |||

| Spilnose taper | Sub Spindle | A2-5 | ||||

| Spindle motor | Sub Spindle 30 min/continue | 7,5 | Kw | |||

| Maximum torque on spindle | Sub Spindle | 57 | Nm | |||

| Spindle speed driven tools | 25-3000 | Rpm | ||||

| Motor driven Tools | 30 min/continue | 3,7 | kW | |||

| Torque motor driven tools | 35 | Nm | ||||

| X-Axis movement | 190 | mm | ||||

| Z-Axis movement | 575 | mm | ||||

| B-axis movement (subspindle to mainspindle) | 585 | mm | ||||

| Minimum indexing C-Axis maim Spindle | 0,001 | ° | ||||

| Minimum Indexing C Axis Sub Spindel | 5 | ° | ||||

| C-Axis index 90° | 1,2 | sec | ||||

| Cutting feedrate X and Z axis | 1-5000 | mm/min | ||||

| Cutting feedrate C-axis | 400 | Rpm | ||||

| Rapid traverse X-Axis | 30 | m/min | ||||

| Rapid traverse Z-Axis | 30 | m/min | ||||

| Rapid traverse B-Axis | 18 | m/min | ||||

| Rapid Speed C-Axis main spindle | 400 | Rpm | ||||

| Number of tools on turret / Driven | 12/12 | |||||

| Tool type | MAZAK VDI 40 | |||||

| Turret indexing 1 pos /180 degr | 0,2/0,6 | sec | ||||

| Size of turning tool | 25 | mm | ||||

| Boorbar size | 40 | mm | ||||

| Max. Diameter Driven Drill | 20 | mm | ||||

| Max. Diameter Mill Driven Toom | 20 | mm | ||||

| Maximum tapping Driven Tool | M 12 | mm | ||||

| Required floorspace | width x depth | 3150 x 1700 | mm | |||

| Height | 2000 | mm | ||||

| Weight | 5350 | kg | ||||

| Complet with | Cycle bar feeder interface | |||||

| LNS Quick Load servo bar feeder/magazine, incl 3 pushers | ||||||

| 12 pieces of fillertubes | ||||||

| Automatic part catcher, usable on main and sub spindle | ||||||

| Main and sub spindle with Hainbuch colletchuck Axfix 65 incl. 2 collets | ||||||

| Subspindle with product ejector | ||||||

| Spindle air blast on main and sub spindle | ||||||

| Chip conveyor side | ||||||

| High pressure coolant 13 bar with additional tank and Filter | ||||||

| Auto power on/of including warm up function | ||||||

| Tooling: | 1 V Type driven tool | |||||

| 2 H Type driven tool | ||||||

| 1 H type Double driven tool (Main and sub spindel) | ||||||

| 1 Cut of holder | ||||||

| 2 Boring bar holders | ||||||

| 2 double boring bar holder (Main and Sub spindle) | ||||||

| 2 Turning holders | ||||||

| 2 double turning holders (Main and sub spindle) | ||||||

| Control options: | Background path check | |||||

| EIA/ISO | ||||||

| Memory 1 Mb | ||||||

| 2nd Spindle aux functions | ||||||

| Synchr. Mill Tapping | ||||||

| User Macros (600) | ||||||

| Total mill spindle drive is revised | ||||||

PRIX HT : sur demande*

* machine disponible sauf vente entre temps

PRIX : Contactez-nous

|

|